4D Printed Hygroscopic Programmable Material Architectures

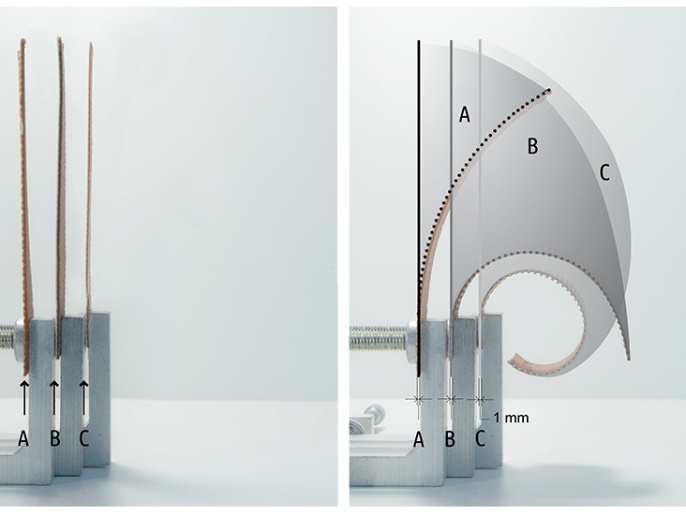

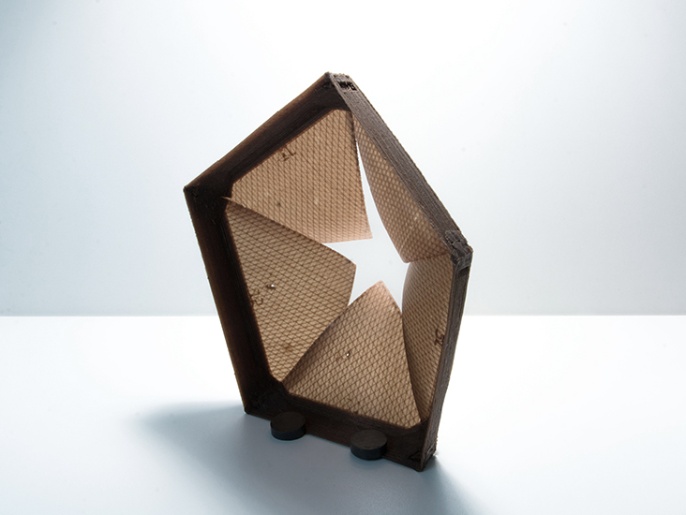

Developing materials that can change their shape in response to external signals, like heat or humidity, is a critical concern for architectural design as it enables designers to develop building components that can be programmed to transform in response to changing environmental conditions. However, developing a stimulus-responsive material requires the architect to extend its level of engagement from the macroscale of the building into the much smaller scale of the material’s micro- and meso-structure. In this thesis, a novel approach for the 4D printing (4DP) of hygroscopic responsive shape-changing mechanisms is proposed and analysed. This approach engages the design of mesoscale technical structures, via a precise material deposition, that harness the anisotropic properties inherent to the fabrication process and the constitution of the printing material itself. Organization models from biological organisms, such as motile plant structures, are abstracted into smart 4D printed techniques to preprogram water induced shape-change using copolymers with embedded cellulose fibrils. This principle enables expansion or contraction forces, whose direction and strength are dependent on the architecture of the 3D printed structure. A series of experiments are described that validate the transfer of known hygroscopic bilayer principles from lamination processes to 3D printing (3DP). They demonstrate the increased programmable control of the 4DP technique through functional gradation, moisture control and multi-phase motion; and present the augmented kinematic capacity of the novel 4DP technique. In addition to the self-shaping mechanisms, the possibilities and challenges of using 4DP structures in architectural applications, such as aperture assemblies and flap mechanisms are discussed. The presented techniques, and bio-inspired approach to material organization, demonstrate the first successful application of differentiated Wood Polymer Composite (WPC) 3DP for programmable hygroscopic shape-change. The experiments can help to form the basis for complex stimulus-responsive building components capable of performing autonomous transformations in technical applications for thermal and moisture regulation.

ICD Institute for Computational Design and Construction - Prof. Achim Menges

Scientific Development

David Correa

Cooperation Partners

Plant Biomechanics Group, University of Freiburg - Dr. Simon Poppinga

Self-Assembly Lab, MIT Massachusetts Institute of Technology - Skylar Tibbits

Research Support

Noztek Ltd.

MakerBot Europe GmbH

Felix Robotics

INDMATEC GmbH

BASF SE

Research Assistants

Belen Torres, Paula Baptista, Alexander Wolkow

Funding

Getty Lab

Natural Sciences and Engineering Research Council of Canada (NSERC)

Selected Publications

Poppinga, S., Correa, D., Bruchmann, B., Menges, A., Speck, T.: 2020, Plant Movements as Concept Generators for the Development of Biomimetic Compliant Mechanisms. Integrative and Comparative Biology vol. 60 no. 1, pp. 1–11. (doi: 10.1093/icb/icaa028)

Correa, D., Poppinga, S., Mylo, M., Westermeier, A., Bruchmann, B., Menges, A., Speck T.: 2020, 4D pine scale: biomimetic 4D printed autonomous scale and flap structures capable of multi-phase movement, Philosophical Transactions of the Royal Society A, 378, pp. 20190445. (doi: 10.1098/rsta.2019.0445)

Correa, D., Menges, A.: 2017, Fused Filament Fabrication for Multi-Kinematic-State Climate Responsive Apertures, in Fabricate – Rethinking Design and Construction [Proceedings of the Fabricate Conference 2017], Stuttgart, pp. 190–195. (ISBN: 978 1 78735 001 4; JSTORE: j.ctt1n7qkg7.30)

Correa, D., Papadopoulou, A., Guberan, C., Jhaveri, N., Reichert, S., Menges, A., and Tibbits, S. : 2015, 3D Printed Wood: Programming Hygroscopic material transformation. 3D Printing and Additive Manufacturing, Volume 2, No.3, Mary Ann Liebert. pp.106-116. DOI: 10.1089/3dp.2015.0022

Correa, D. Menges, A.: 2015, 3D Printed Hygroscopic Programmable Material Systems, in Sabin, J., Gutierrez, P., Santangelo, C., MRS Proceedings, Volume 1800, mrss15-2134303 DOI:10.1557/opl.2015.644.

Correa, D., Krieg, O., Menges, A., Reichert, S., Rinderspacher, K.: 2013, HygroSkin: A prototype project for the development of a constructional and climate responsive architectural system based on the elastic and hygroscopic properties of wood, in: Beesley, P., Khan, O., Stacey, M. (Eds.), Proceedings of the 33rd Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA) – Adaptive Architecture, Waterloo/Buffalo/Nottingham, pp. 33-42. (ISBN 978-1-926724-22-5)

Reichert, S., Menges, A., Correa, D.: 2014, Meteorosensitive Architecture: Biomimetic Building Skins Based on Materially Embedded and Hygroscopically Enabled Responsiveness, CAD Journal, Elsevier, June 2014, DOI: 10.1016/j.cad.2014.02.010 (ISSN 0010-4485)

Contact Information

David Correa

M.Arch., B. SciDoctoral Candidate