Autonomous Granular Materials in Architecture (AGMA)

The project Autonomous Granular Materials in Architecture (AGMA) investigates the use of autonomously shape-changing particles in a granular material for architectural structures. Granular materials are systems with high particle numbers in which the individual particles are not firmly bound to each other, but are only in loose frictional contact. Since these materials are not bound, they can be reconfigured and completely recycled. In a designed granular material the individual particles are defined in their geometry and materiality. This allows to calibrate the behaviour of the overall granular material through the particle design. Going even further, autonomously shape-changing particles can independently transform themselves into different basic geometric types and thus generate different architectural properties of the entire granular material.

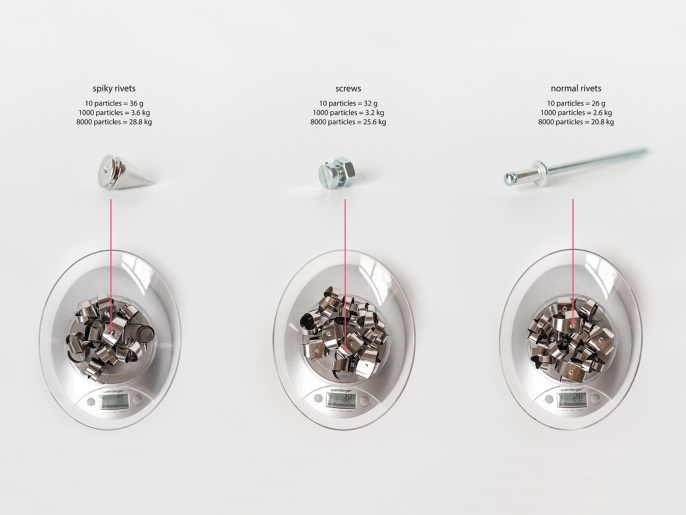

A bimetal of MnCu18Ni10 as the high-expansion side and FeNi36 as the low-expansion side was used for the fabrication of the shape-changing particles. With a high operating temperature of a maximum of 350 °C this ensured that the shape-change did not occur under regular temperature fluctuations but needed to be induced by directly applying external heat to the system. The material is very thin with a thickness of 0.115 mm which allows a rapid shape-change yet is one of the greatest constraints for the size and strength of the particles. The particles were fabricated using waterjet cutting.

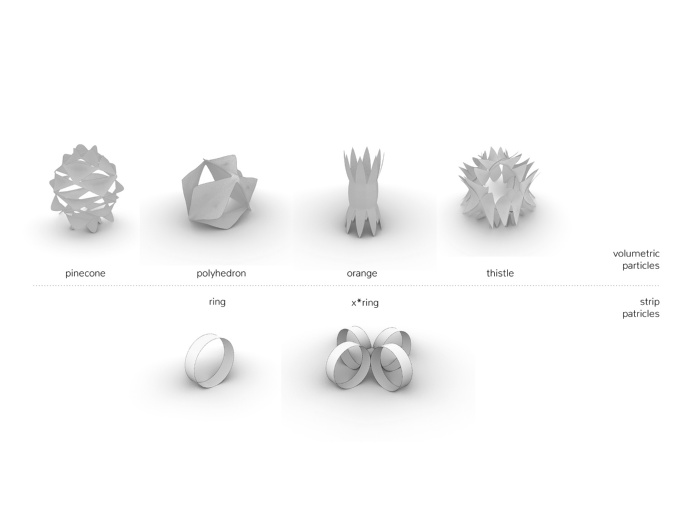

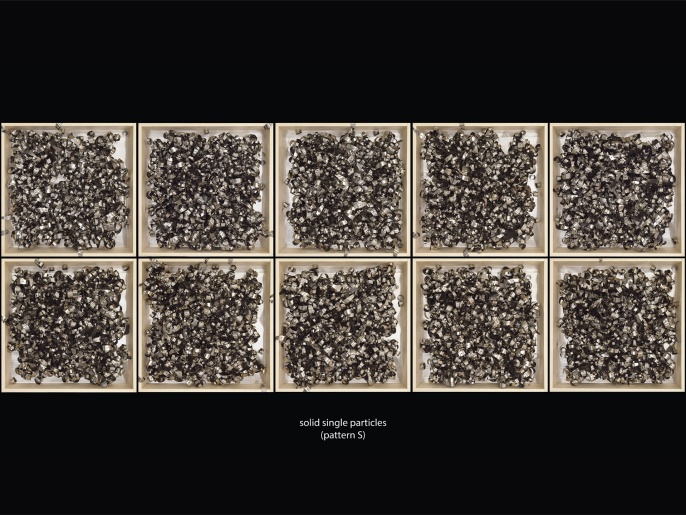

Several possible particle geometries were explored ranging from volumetric designs to strips. Ultimately single strips and crossed strips—or assembled—performed best with respect to interlocking and cost per unit.

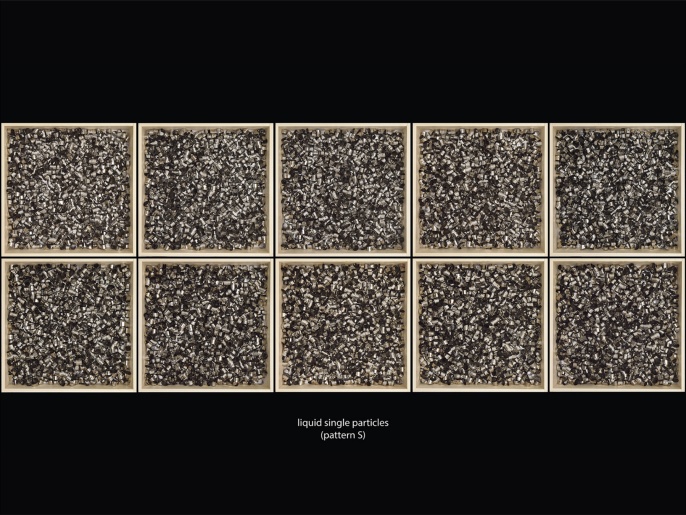

Single and assembled strips were tested both separately and in a 50/50 mix for their interlocking behaviour. The 50/50 mixture showed higher interlocking between the particles than assembled strips and had a substantially higher built volume than single strips.

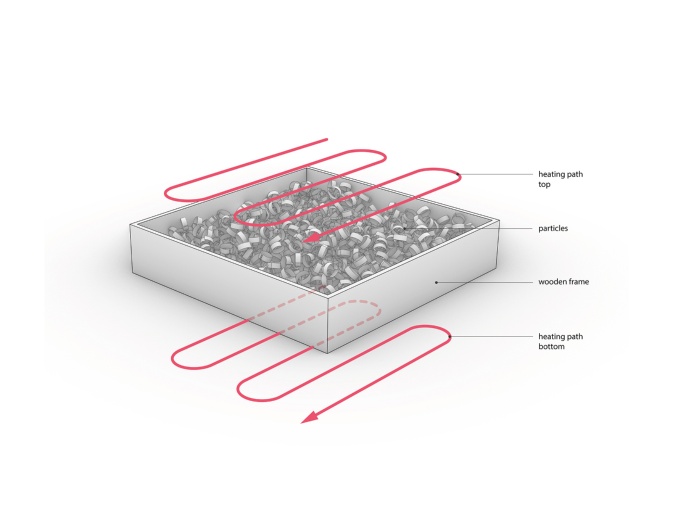

The final prototype was built using a mixture of roughly 5000 particles made from single strips and 5000 made from assembled strips. It had a length of 3.20 m, a thickness of 0.06–0.15 m, and a width of 1.0 m. It was assembled in eight separate components which were each heated from the top and bottom simultaneously using a wooden frame as a mold. Then the interlocked particles were positioned next to each other and joined at the edge by heating the seams, adding particles and letting the edge-particles interlock. After cooling, the surfaces formed a surface that was hung at a height of 2 m with a cable system. For disassembly, the structure was heated from the bottom, allowing the particles to disentangle and drop to the ground.

PROJECT TEAM

ICD Institute for Computational Design and Construction

Dr.-Ing. Karola Dierichs (PI)

Denitsa Koleva, M.Sc.

with: Eda Özdemir, M.Sc.; Vaia Tsiokou, M.Sc.

Scientific Collaboration:

Jaeger Lab, University of Chicago

Professor Heinrich M. Jaeger, Ph.D.

Institute for Multiscale Simulation, Friedrich-Alexander-Universität Erlangen-Nürnberg

Professor Dr. Thorsten Pöschel

Project Funding:

Terra incognita, University of Stuttgart, DFG

Manufacturing:

Auerhammer Metallwerk GmbH

Roy Hohlfeld Wasserstrahlschneiden