Timber Construction 4.0: Potentials of Industry 4.0 for Prefabrication in Timber Construction

The project explored the key principles of robotic timber construction in the context of Industry 4.0 and developed the basis of a general framework for its further development. In-depth literature research and analysis revealed the importance of organizational flexibility in the construction industry. To align digital technologies for the construction industry, this understanding is of fundamental relevance for any further development. As the common conversations regarding the future of digital construction mostly focus on standardization measures and productification, this position opens a new developmental avenue in which relevant stakeholders in both academia and business can engage. Although technological development and intensified research is still needed to enable truly profitable project-based, largely automated robotic fabrication of wood structures, the work in the project shows clear research trajectories and potentials of these technologies.

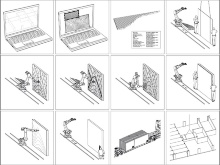

Flexible, project-based robotic fabrication in wood construction.

We show how robotic manufacturing methods can be flexibly embedded in the established production networks of timber construction. This project-based technology set-up allows timber construction companies to continue to react agilely to market conditions and environmental parameters. This lays the foundation for technology transfer from research to industry.

Performance of robotic manufacturing in wood construction

Through a largescale case study of the BUGA Wood Pavilion, we demonstrate the extended performative qualities that are possible to achieve through the combination of digital fabrication methods and traditional craftsmanship. Since the building had to comply with all building regulations, this step provides significant insight into the actual potentials of integrative computational design and digital fabrication.

Concepts of the fourth industrial revolution in the construction industry

Through the literature research, the potential of Industry 4.0’s common themes of increased networking and sensory equipment of manufacturing hardware (i.e. IoT) were found less important for the construction industry. Rather, the research identified the potential of new organizational routines in the manufacturing industry that are focusing on increased flexibility of production automation. This raises the possibility of a convergence of the two industries: While a highly automated manufacturing industry seeks agility, the already flexibly organized construction industry strives for more automation. We found it is of crucial importance that decision makers in the construction industry pay attention to maintaining organizational flexibility and agility when introducing digital automation technologies.

Increasing the proportion of wood construction through project-based automation for multi-story construction.

Through the second case study, it was possible to shed light on fundamental parameters that appear necessary for increasing the proportion of wood construction in multi-story buildings. In order to open up market potentials for timber construction in building typologies in which stringent grids are dominant and prohibit a broad application of timber construction across all building types, it is necessary to develop adaptive building systems that can adapt to the most diverse floor plan structures. The project developed two exemplary concepts of how this can be achieved.

PUBLICATIONS

Wagner, H. J., Groenewolt, A., Alvarez, M., Menges, A.: 2020, Towards Digital Automation Flexibility in Large-Scale Timber Construction: Integrative Robotic Prefabrication and Co-Design of the BUGA Wood Pavilion, Construction Robotics, Springer, 2020. (https://doi.org/10.1007/s41693-020-00038-5)

Wagner, H. J., Alvarez, M., Bhiri, Z., Buck, M., Menges, A.: 2020, Flexible and transportable robotic timber construction platform – TIM, Automation in Construction, Volume 120, December 2020. (https://doi.org/10.1016/j.autcon.2020.103400)

Wagner, H. J., Aicher, S., Balange, L., Basalla, U., Schwieger, V., Menges, A.: 2021, Qualities of the Unique: Accuracy- and Process-Controll in Project-based Robotic Timber Construction, in Proceedings of the World Conference in Timber Engineering, Santiago di Chile, Chile (accepted)

Bechert, S., Sonntag, D., Aldinger, L., & Knippers, J.: 2020, Statische Modellierung und Berechnung von Segmentschalen aus Holz. In B. Oesterle, M. Bischoff, & malte Von Scheven (Eds.), Baustatik - Baupraxis 14 (Vol. 14, pp. 407–414).

PROJECT TEAM

ICD Institute for Computational Design and Construction

Prof. A. Menges (PI), Hans Jakob Wagner

ITKE Institute of Building Structures and Structural Design

Prof. J. Knippers, Simon Bechert

ASSOCIATED PROJECT PARTNERS

Müllerblaustein Holzbau GmbH, Reinhold Müller

Schlosser Holzbau GmbH, Josef Schlosser

WeberHaus GmbH & Co., Hans Weber

Kampa GmbH, Josef Haas

Cheret Bozic Architekten, Prof. Peter Cheret

Knippers Helbig Advanced Engineering, Prof. Dr.-Ing. Jan Knippers

Homag Group, Ulrich Doll

Kuka Roboter GmbH, Frank Zimmermann

PROJECT FUNDING

EFRE European Union

Land Baden-Württemberg