The goal of this project was to use timber veneer as a starting point in order to develop a system which is based on material-specific properties and thus enables a high degree of morphological adaptation responding to external conditions. The design process was characterized by the close observation of a series of continuous, specific physical experiments and research regarding the material reactions to various loadings of mechanical forces; the data was compiled in a structured collection. Conclusions concerning the system-determining parameters such as assembly logic, manufacturing technique and environmental performance were drawn from these observations and measurements and served as a guide line for the further development.

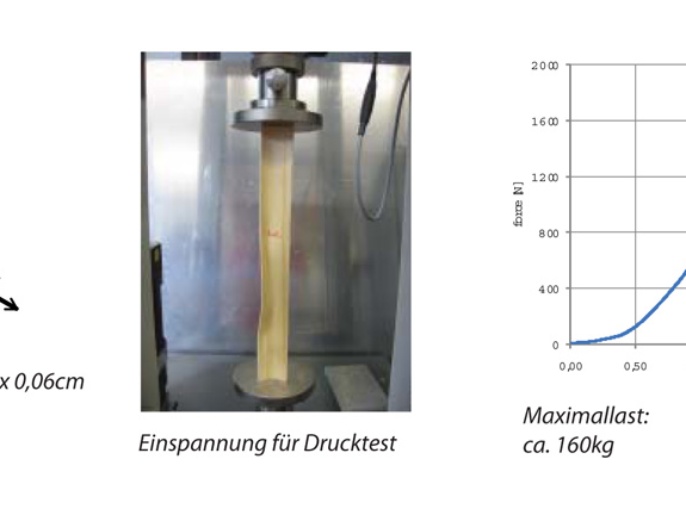

After an initial analysis of the structural and material-specific properties of wood in general (growth process, adaptivity, etc.) a serious of experiments with the use of timber veneer strips was conducted, which aimed at the understanding of the bending- and torsional structural behaviour as well as the response of the workpieces to physical factors such as heat and humidity and its effect on the mechanical properties. The team developed a “catalogue of properties” (Eigenschaftskatalog) which served as a basis for the design development. After a definition of the starting material a series of differentiated phenotypes was generated. This was achieved through the manipulation of form-defining parameters (e.g. strip-geometry, glue-regions, etc.) which affected the overall geometry, which differed largely in performative capabilities. “Assembly rules” defined the generative process, which incorporated anisotropic and hygroscopic properties of the material and therewith ensured the individual configurations were aligned with the inherent material logic. Secondary, the amount of material used was a fundamental criterion. Thirdly, computer-based fabrication and assembly methods were integrated and a prototypical installation was realized with minimal technical effort in terms of tools or craftsmanship.

This project achieved to prove the early stated hypothesis that through the integration of a material-specific assembly logic and minimal means of adaptive geometric variation of timber-veneer a material system can be developed which combines inherent structural capacities, simple fabrication methods without comprimizing a high degree of formal flexibility.

The prototype was shown as part of the BMW Exhibition “Freiräume Gestalten” in Munich and Berlin from September 2009 until February 2010.

Due to its anisotrophic microstructure, laterally bent timber strips can be assembled longitudinally to create a very rigid lightweight structure. The students also developed a strategy that allows for local bending in order to address complex shapes with a population of strips.

Material Systems I Studio Brief