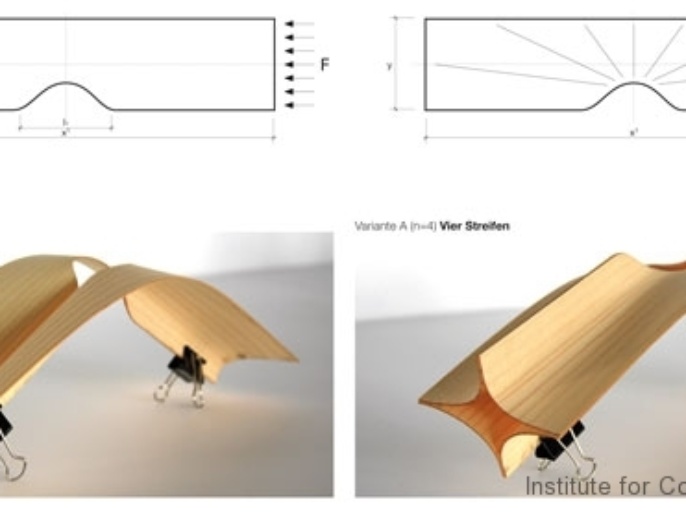

Through the ever-increasing Integration of computer-based methods of generative manufacturing processes in architecture the designer gains new possibilities to incorporate and integrate reciprocal interrelations between Umwelt, material, space and structure into the design process effectively. In this project such possibilities were investigated through physical experiments and the use of computer-based generative algorithms based on the material wood. The design development was based on a simple underlying fabrication method which was an integral part of the entire project: By varying the cutting pattern of a veneer-strip, the cross-sectional modulus was strategically weakened and by applying external forces onto the strip a specific „Verformungsfigur" were induced, which led to the development of an entire structure.

As a part of the first series of experiments a general hypothesis was formulated, which was underlying all successive investigations and served as a basis for the following generative processes: By joining the two ends of a veneer-strip differentiated geometries of bent strip-assemblies can be created. In three successive experiment series the shapes were analyzed with regards to their relationship to various parameters. In the first set of experiments the bending behavior of strips of constant cross-sectional geometry was examined. In a second set of experiments the repercussions of symmetric and later on asymmetric variations of the strip-width on the general "Verformungsfigur" and related parameters were investigated.

The fact, that even a very simple manipulation set such as the position, geometry and number of a cut along a strip could be varied almost infinitely, resulted in numerous variations and therefore methods for joining. Because of that, the focus for the final prototype lay on the development of a intelligent and performative assembly logic on the meso-structural level. This was achieved by the parallel development of a digital parametric model, which mimicked the observed behaviors geometrically and convoluted in a timber surface compound.

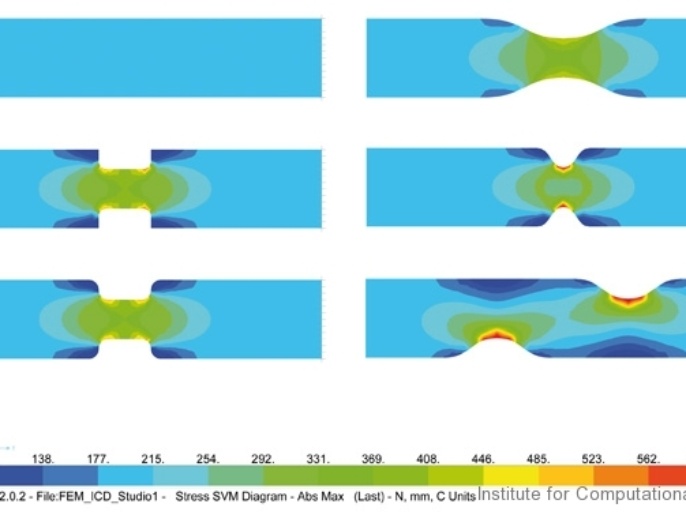

The specific bending deformation of a veneer strip is controlled through sectional changes in geometry. Asymetrical geometries create multi-dimensional curvature (Rotary motion along the longitudinal axis) on axially supported strips. With this predictability and CNC controlled high precision manufacturing technology, complex curvature can be created through a population of simple strips.

Material Systems I Studio Brief