Tailored Structures - Adaptive Robotic Fabrication of Sewn Veneer Composites

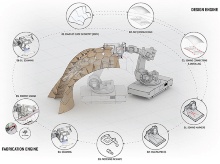

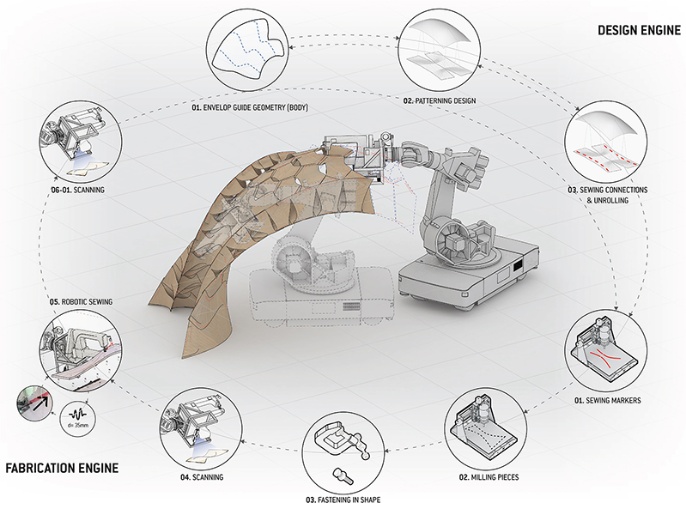

Tailored Structures investigates the use of robotics and sensing mechanisms in combination with industrial sewing techniques to explore a new way of fabricating wood shells.

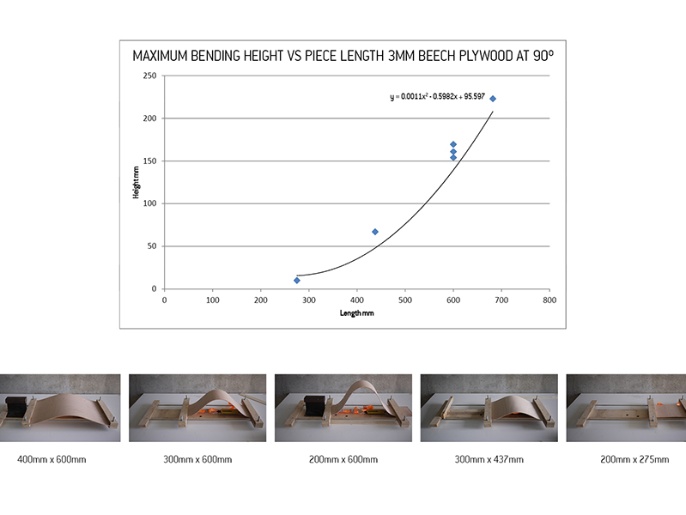

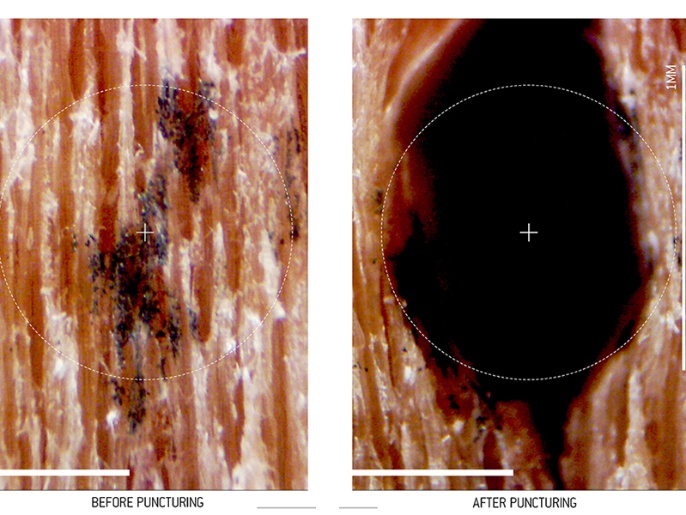

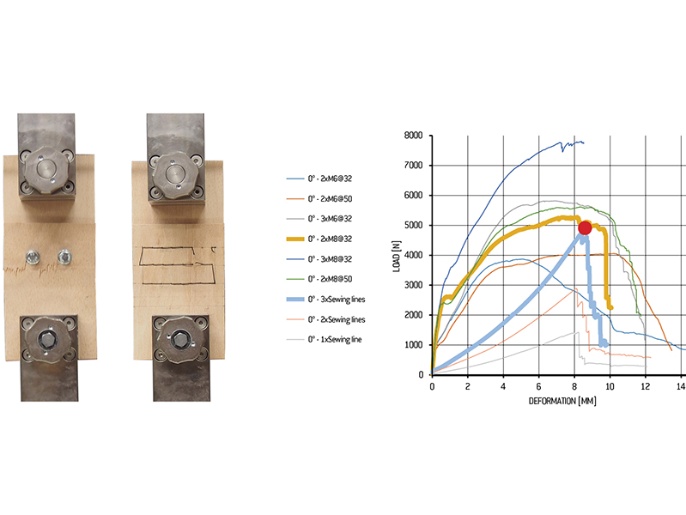

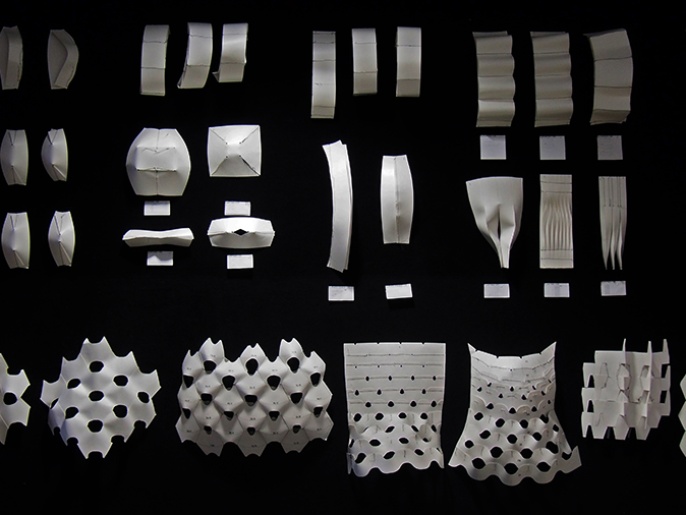

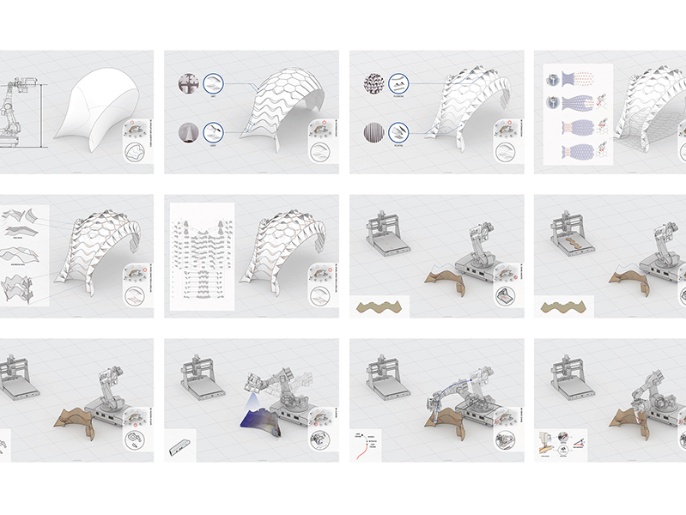

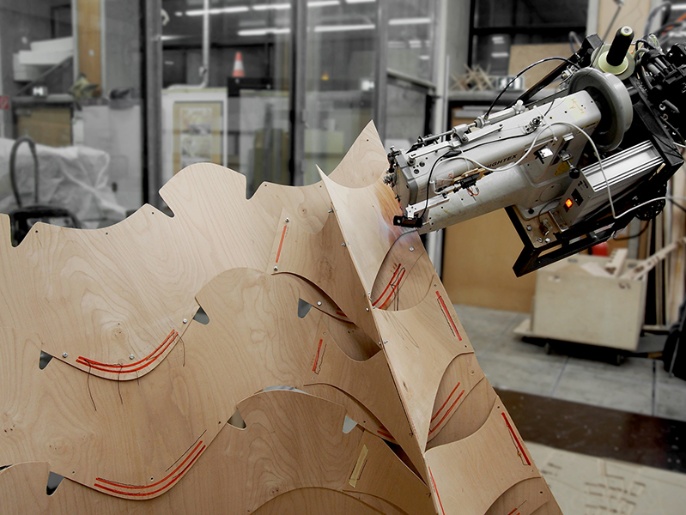

The intelligence of two dimensional textile patterning techniques commonly used in fashion, inspires the design and assembly of 3mm beech plywood segments. Sewing is proposed as a new construction joint with comparable strength to wood glue & bolts, but with the added capacity to sew thin material close to its edges and against tension. Tailored wood segments held in elastic bending form three dimensional curved structures that are sewn together from two dimensional pieces.

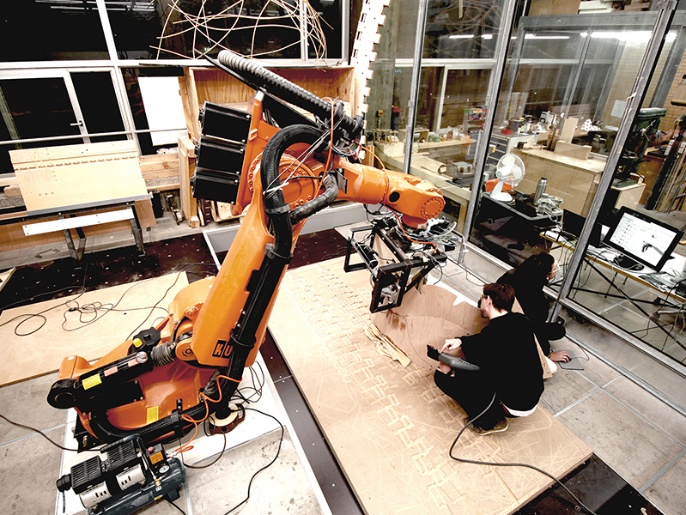

In a human-robot collaborative fabrication technique, wood segments are elastically bent into place against each other. After being clamped temporarily, they are joined permanently by a sewn connection.

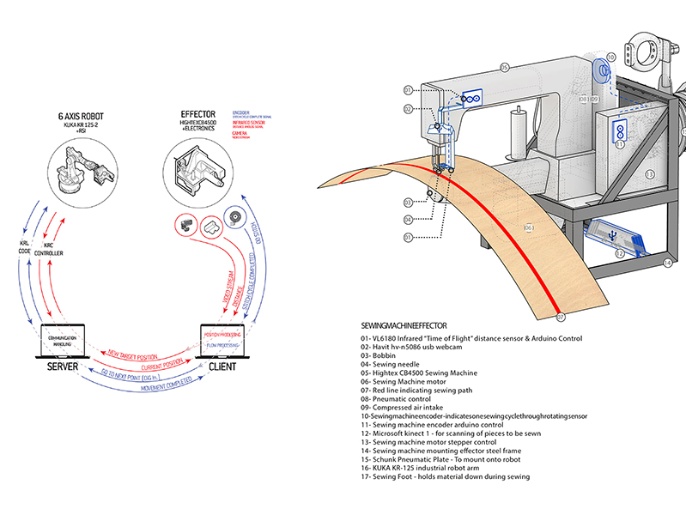

Liberating an industrial sewing machine from its typical stationary workspace makes it possible to work on larger pieces. The sewing machine, mounted onto a 6-axis industrial robot is able to move around pieces that it will sew. In situ, the robot and sewing machine are mounted on a mobile cart that enables access to building-scale components. Workpiece geometry is constantly surveyed by the use of 3D scanning, which provides information to access the workpiece. Once the sewing machine has accessed the area to sew, red markers guide the sewing machine to lay the stitches down by use of color detection through cameras and distance sensors.

The tectonic system, derives its geometry from the sewing machine’s workspace envelope - maximizing the system’s coverage. An elastically formed wooden shell takes account of bending capacity to provide gradated amounts of coverage, openness and fenestration.

ITECH M.Sc. Thesis Project 2016: Tailored Structures - Adaptive Robotic Fabrication of Sewn Veneer Composites

Martín Alvarez, Erik Martínez

Thesis Advisers: Ehsan Baharlou, Oliver Krieg, Tobias Schwinn, Lauren Vasey

Thesis Supervisor: Prof. Achim Menges

Second Supervisor: Prof. Jan Knippers

Tailored Structures investigates the use of robotics and sensing mechanisms in combination with industrial sewing techniques to explore a new way of fabricating wood shells.

The intelligence of two dimensional textile patterning techniques commonly used in fashion, inspires the design and assembly of 3mm beech plywood segments. Sewing is proposed as a new construction joint with comparable strength to wood glue & bolts, but with the added capacity to sew thin material close to its edges and against tension. Tailored wood segments held in elastic bending form three dimensional curved structures that are sewn together from two dimensional pieces.

In a human-robot collaborative fabrication technique, wood segments are elastically bent into place against each other. After being clamped temporarily, they are joined permanently by a sewn connection.

Liberating an industrial sewing machine from its typical stationary workspace makes it possible to work on larger pieces. The sewing machine, mounted onto a 6-axis industrial robot is able to move around pieces that it will sew. In situ, the robot and sewing machine are mounted on a mobile cart that enables access to building-scale components. Workpiece geometry is constantly surveyed by the use of 3D scanning, which provides information to access the workpiece. Once the sewing machine has accessed the area to sew, red markers guide the sewing machine to lay the stitches down by use of color detection through cameras and distance sensors.

The tectonic system, derives its geometry from the sewing machine’s workspace envelope - maximizing the system’s coverage. An elastically formed wooden shell takes account of bending capacity to provide gradated amounts of coverage, openness and fenestration.

ITECH M.Sc. Thesis Project 2016: Tailored Structures - Adaptive Robotic Fabrication of Sewn Veneer Composites

Martín Alvarez, Erik Martínez

Thesis Advisers: Ehsan Baharlou, Oliver Krieg, Tobias Schwinn, Lauren Vasey

Thesis Supervisor: Prof. Achim Menges

Second Supervisor: Prof. Jan Knippers