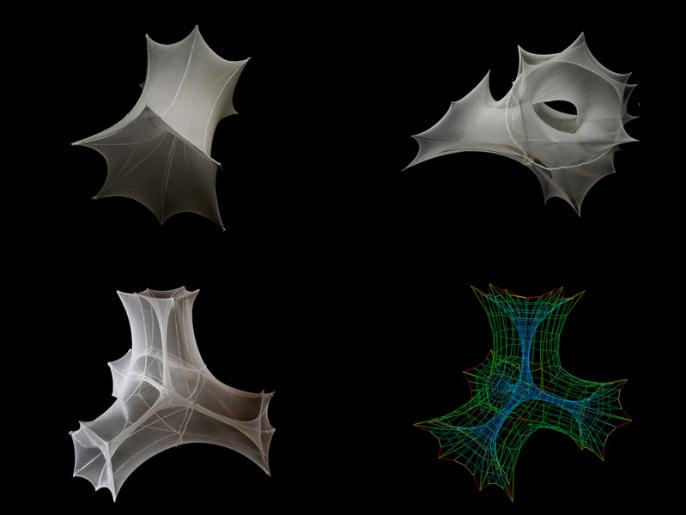

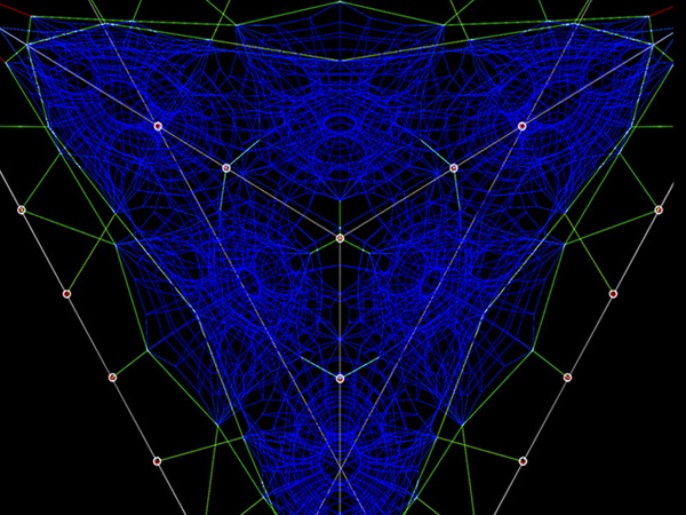

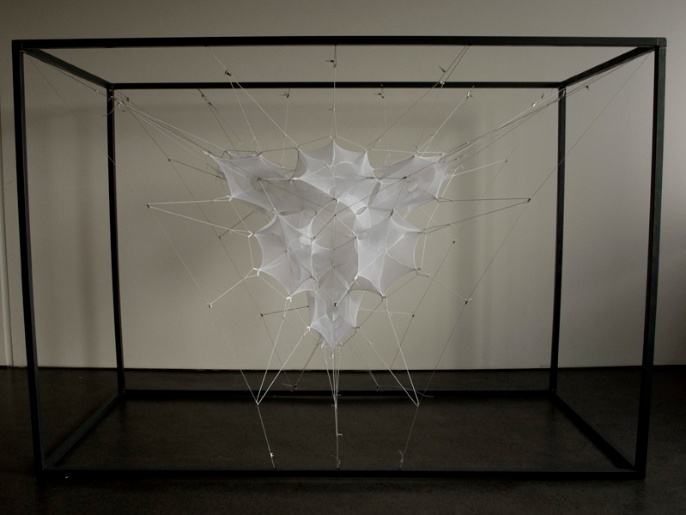

This project studies the possibility of advanced geometric complexity within a continuous tensioned surface and mesh structure. Stability of a purely tensioned structure relies upon an equilibrium (but not equalization) of distributed tension forces throughout all interconnected elements. In this project, tension is moving continually through surface and mesh elements, whose behavior is decidedly different. Thus, as the complexity in geometry (and topology) advances the control and distribution of tension forces exponentially increases. Complexity arises from the arrangement of a series of hyper-toroidal cells, each of which has a both inner and outer surface. This evolved through a series of physical and computational studies beginning with a basic torus element. Tension is distributed between the cell surfaces, but also through a network of fixed-node cables. The cables allow for point loads to be invested in the structure at its most extreme moments (mainly the points that are most distant from the boundary, where tension usually is highly dissipated).

The studies for this structure where developed in Processing using a simulation engine based on particles and springs. The particle system is constrained to recognize some basic behaviors of tensioned surfaces and meshes. The ultimate calibration to material information occurred through the simultaneous translation of geometry and force descriptions from the Processing model. Specifications for material performance were built into the algorithms so that templates of the un-tensioned surfaces could be generated for fabrication. The cutting patterns were utilized on a large-scale cut plotter to manufacture the panels for the final geometry.

Deep Surface Prototype seminar brief