DADA 2015 Digital Factory Workshop

CAUP Tongji University and ArchiUnion, Shanghai

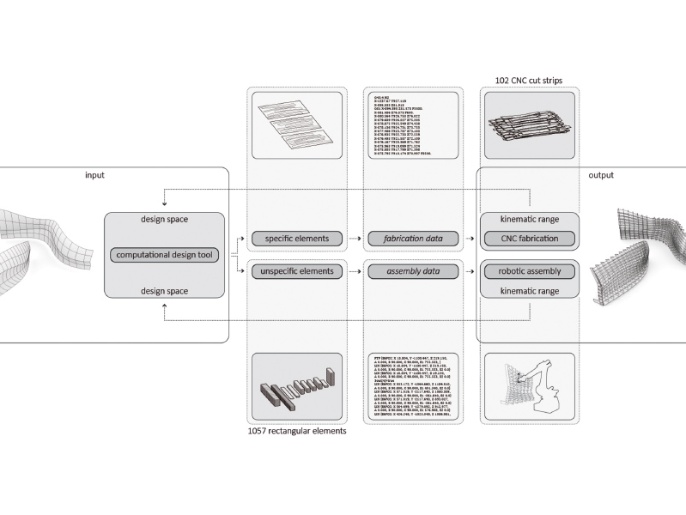

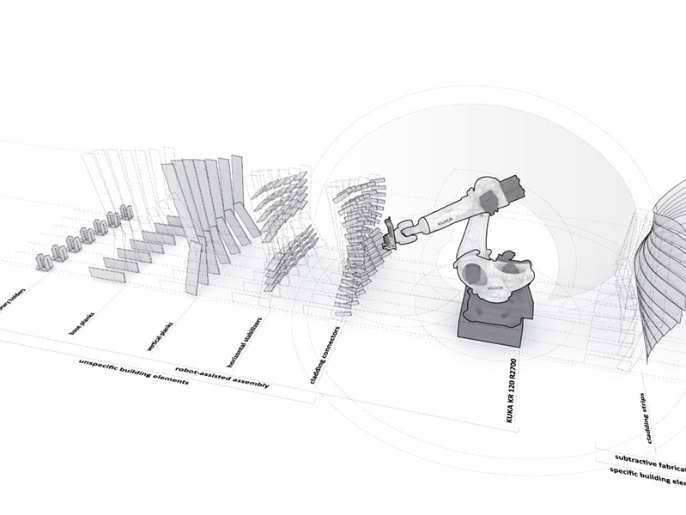

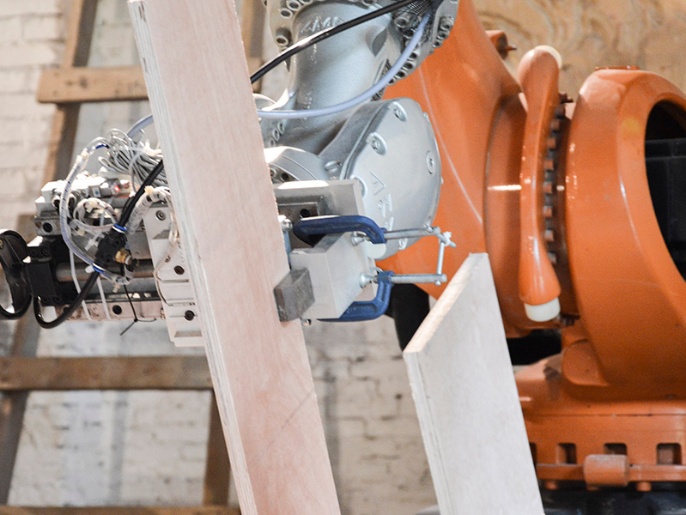

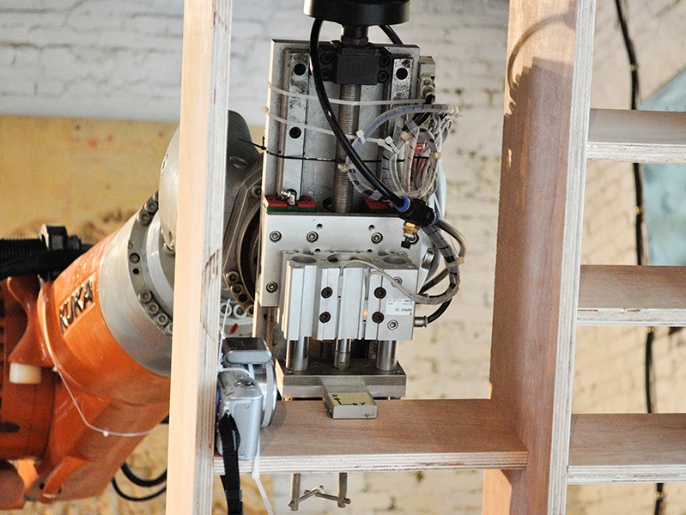

The DADA Digital Factory workshop “Robot-Assisted Assembly in Wood Construction” led by Abel Groenewolt, Oliver David Krieg, and Achim Menges explores a digital fabrication concept that allows the construction of complex geometry without relying on elaborate measuring techniques or geometric specificity of the building parts. By using an industrial robot as an assembly assistant, simple, regularly shaped objects can be accurately placed at any desired location. In effect, by encoding the geometric specificity in the assembly process instead of the building elements, elaborate timber structures can be fabricated out of standard and widely available building materials.

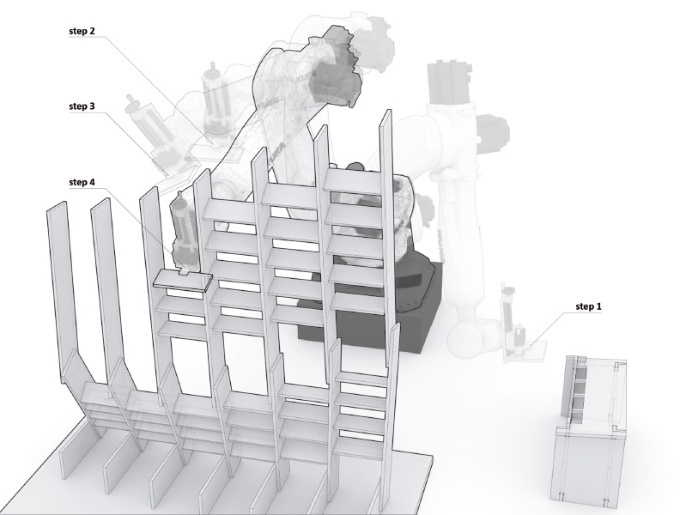

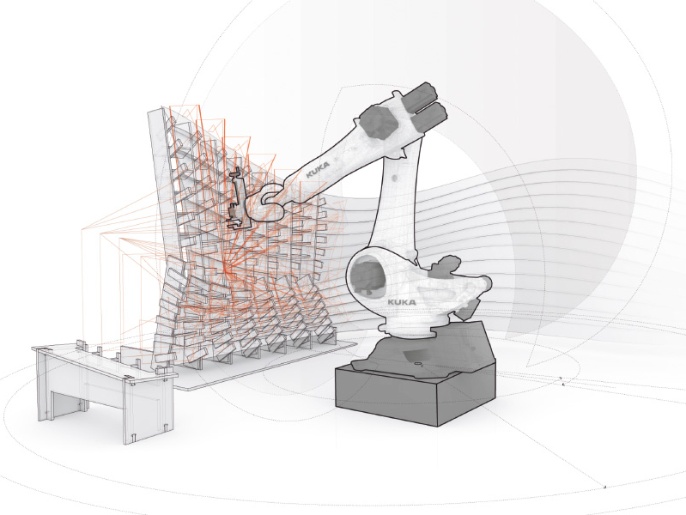

Following this novel fabrication paradigm, robotic assembly of off-the-shelf building elements is employed to build pre-fabricated modules of a doubly curved timber frame construction. These modules fit within the working space of an industrial robot and can easily be transported. Once positioned on-site, the modules are combined with a cladding layer previously produced with a more common production method: precise CNC milling of unique parts.

By combining these two approaches - robotic assembly of unspecific elements and subtractive CNC fabrication of highly specific parts - the strengths of the various tools and actors in the process are employed strategically: the industrial robot works in a controlled environment assembling modules that fit within its reach, while human labour is mostly employed on site, assembling pieces with pre-drilled screw holes that can only be placed in a single way, thus also avoiding the need to measure. This results in a very efficient production for both pre-fabrication and on-site assembly.

During the workshop the students were introduced to a computational design tool that was specifically developed for this project. Taking a double-curved design surface as an input, the tool generates a buildable structure within the material and machine constraints. A simulation of the robotic assembly process and export of robot control files are fully integrated in the computational design process. The closed digital chain from design to fabrication not only allows for innovative pre-fabrication in timber construction, but also for a re-interpretation of wooden architecture.

ICD Institute for Computational Design and Construction

Prof. Achim Menges, Abel Groenewolt, Oliver David Krieg, with Jian Ming Huang

Participants

Shi Xinyu, Li Yutong, Gu Xiaolin, Hu Jialiang, Zheng Xin, Liu Yang, Zhang Shiqi, He Yiwen, Liu Jingrui, Wu Chaoran, Du Jie

Organized and Supported by

DADA 2015 International Conference and Exhibition

CAUP Tongji University, Shanghai

ArchiUnion, Shanghai - Prof. Philip F. Yuan