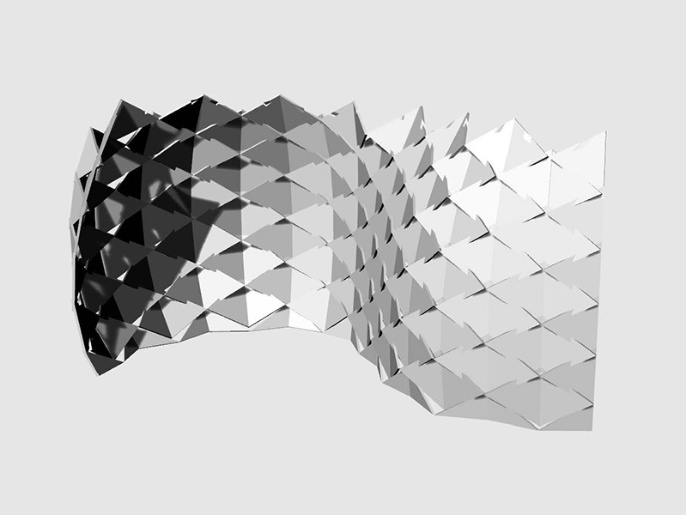

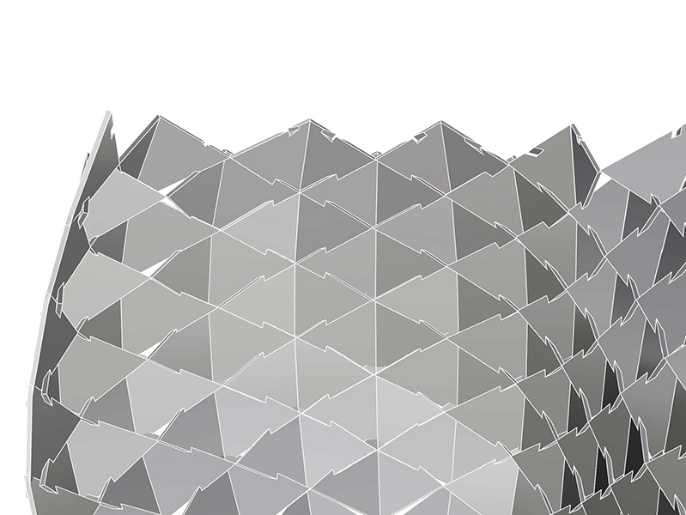

Wood Plate Morphologies

Faculty of Art, Design and Architecture at Monash University, Melbourne

In the past decade, digital fabrication involving industrial robot arms, aka robotic fabrication, has increasingly been adopted in the context of digital fabrication research in architecture. The premise of robotic fabrication is that it offers new possibilities for the design and fabrication of novel and performative structures. Compared to the limited design space of established computer-numerically controlled fabrication processes, robotic fabrication not only opens up additional degrees of freedom for geometrical differentiation due to the kinematic freedom the articulated robot arm; it also allows for the development of entirely custom processes and project-specific configurations. Consequently, the concept of morphospaces provides an analytical method for the description of the relation between a specific machine setup and the theoretical space of producible geometry (Menges, 2013).

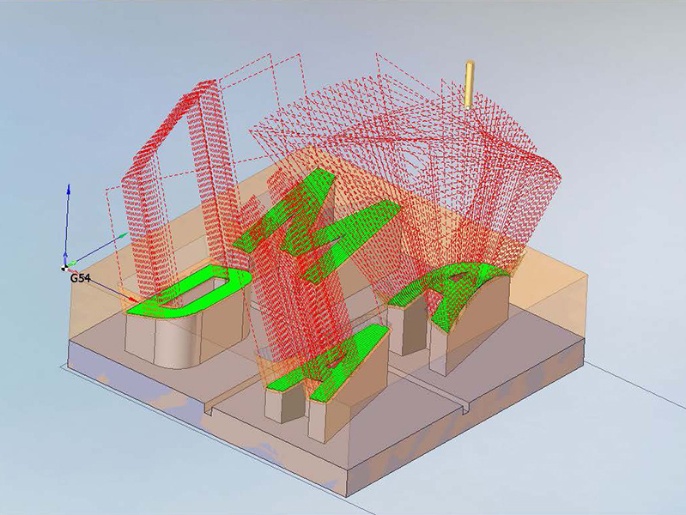

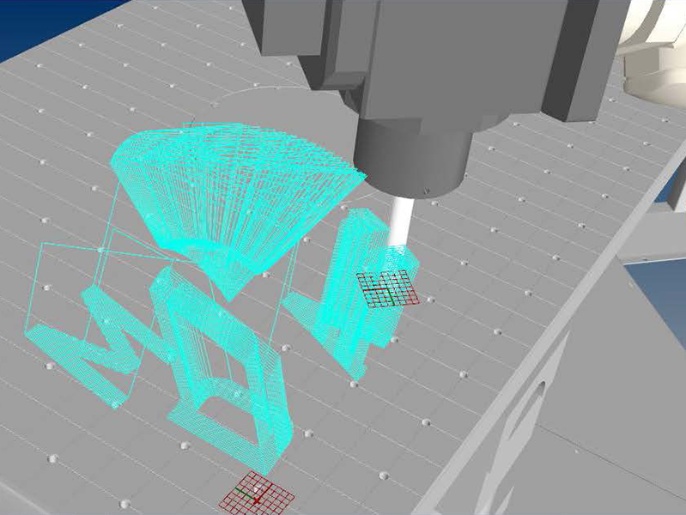

Among the established fabrication processes, numerically controlled milling particularly benefits from the introduction of industrial robotics. Not only can established fabrication cycles & strategies such as roughing, finishing, flank and spot milling be translated into robotic processes; new and custom strategies that take advantage of the degrees of freedoms of the articulated robot arms can be developed in relation to the specific geometrical requirements of a design. Furthermore, the development of custom strategies that aim at a reciprocal relation between design and fabrication lead to a rethinking of the established sequential and unidirectional digital design to fabrication workflow towards the integration of fabrication parameters, digital design exploration, and kinematic simulation into production immanent design environments (Brell-Cokcan & Braumann, 2010).

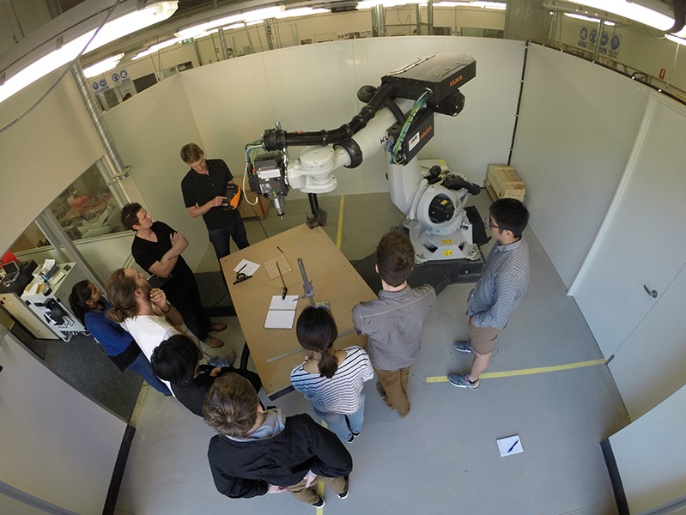

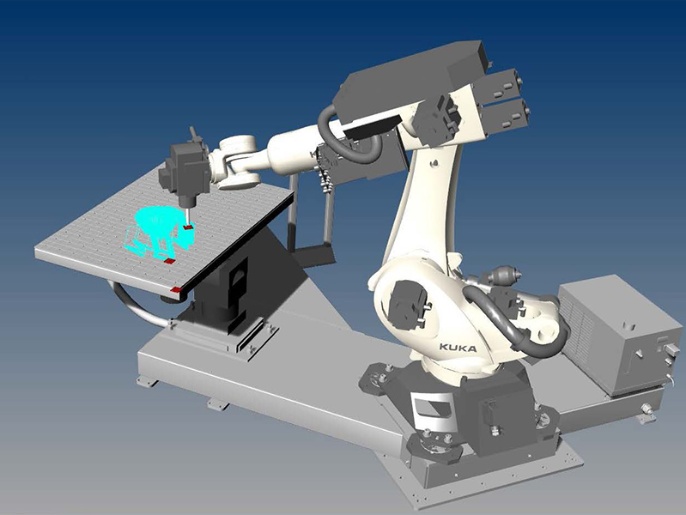

With the recent establishment of a 7-axis robotic fabrication facility consisting of a 6-axis KUKA KR210 R2700 robot fitted with a HSD 10kW spindle and an external axis used as turntable, the Faculty of Art, Design, and Architecture at Monash University, Melbourne, has not only joined the robotic fabrication community, but has also equipped itself to actively explore the domain beyond the known limits of existing fabrication processes and therefore positioned itself to contribute to a growing international body of work in the field of robotic fabrication in architecture.

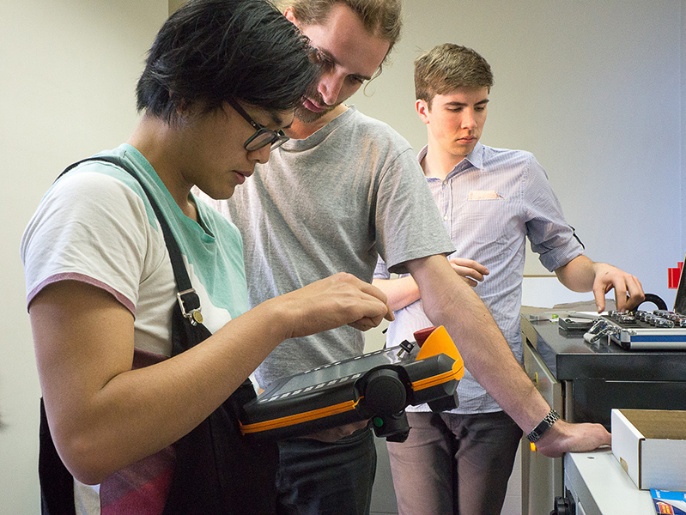

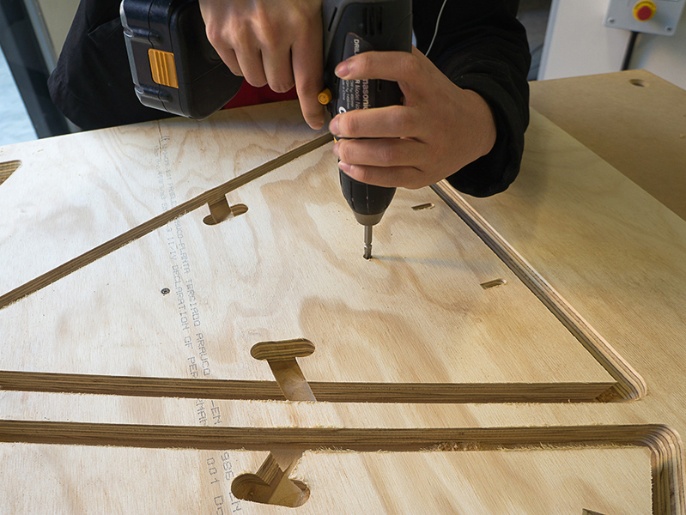

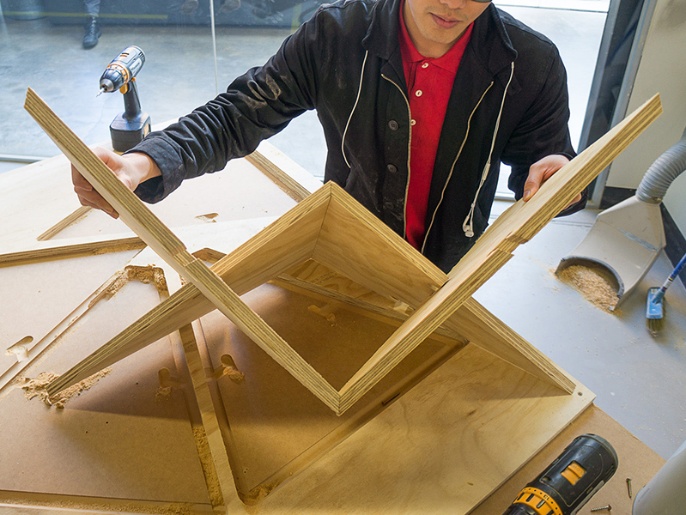

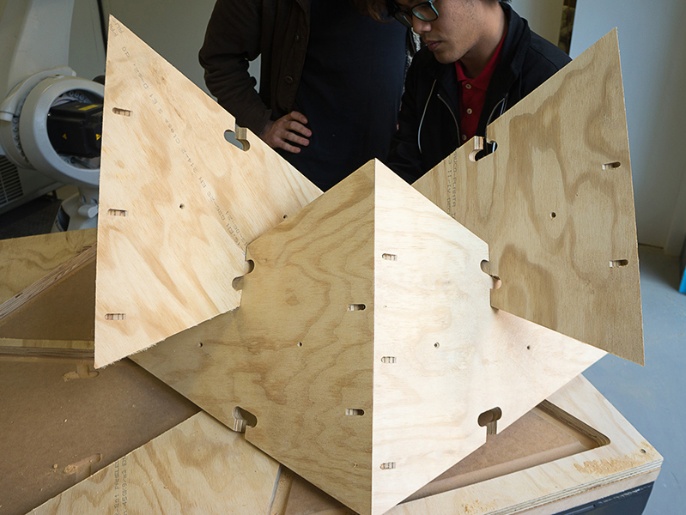

From Sep 22-26, Tobias Schwinn taught a robotic milling workshop that the Faculty of Art, Design, and Architecture at Monash University, Melbourne. The workshop's scope ranged from the basics of the robotic milling process including the handling of the physical tools and best practices to more advanced topics such as simulation of 7-axis robot kinematics, code generation, and the development of custom milling strategies. A particular focus was the integration of robotic fabrication into a robust digital workflow that takes advantage of established CAM knowledge and processes, but at the same time is open and can be incrementally expanded and customized. The processes were tested through the design, fabrication and assembly of a prototypical timber structure.

The workshop was organised by Prof. Tim Schork, MADA and supported by MADA Materials and Processes Lab.

(softwares)

SprutCAM

Rhinoceros with Grasshopper plugin

Sandbox Topology Addon for Grasshopper

ICD Robot Toolbox for Grasshopper

(schedule)

Monday, September 22:

Robot and tool handling

Introduction to standard milling processes

Tuesday, September 23:

Simulation of robot kinematics and code generation

Robotic milling tests

Lecture: Wood Plate Morphologies

Wednesday, September 24:

Strategies of 7-axis robot control

Robotic milling tests

Thursday, September 25:

Design of prototype and detail development

Robotic milling tests

Friday, September 26:

Robotic fabrication of prototype and assembly