Personalised 3D- and 4D-Printing of programmable, self-adjusting and multifunctional Material Systems for Sports and Medical Applications

The research project “4DmultiMATS” explores a novel mode of responsiveness based on structured material assemblies and differentiation strategies, through the 4D printing of self-regulating, multifunctional material systems for sports and medical applications. Inspired by natural role models, the 4D printed material systems – like living beings – can actively and passively adapt their shapes and functions through the application of external stimuli such as pressure, temperature, humidity, pH and light.

This research project brings together plant biomechanics with polymer chemistry, medicine, computational design as well as digital fabrication. Through material design, biological motion analysis, and biomimetic additive manufacturing, 4DmultiMATS achieves shape changing personalized orthotics with adaptive reinforcement. By autonomously self-regulating, printed structures can increase the wearing comfort of prostheses, protective vests, bandages, and orthoses, as well as support wound healing (e.g. of burns) and also avoid skin irritation due to friction. Minimally invasive 4D printed wound dressings utilize self-regulating shape change to unfold, conform to the wound, seal large bone defects, and promote tissue regeneration.

The research of 4DmultiMATS is accompanied and advised by an industrial consortium of companies from all areas relevant to this project. Together, the potential of these printed self-regulating, multifunctional material systems for industrial use will be evaluated and transfer to technology will be promoted at an early stage.

Multifunctional Wearable Device

PROJECT TEAM

Institute of Macro Molecular Chemistry & Freiburg Centre of Material Research, University of Freiburg

Prof. Dr. Rolf Mülhaupt (Project Coordinator), Benjamin Stolz

Plant Biomechanics Group Freiburg, University of Freiburg

Prof. Dr. Thomas Speck, Dr. Marc Thielen, Dr. Simon Poppinga

Oral Biotechnology, Freiburg University Hospital

Prof. Dr. Thorsten Steinberg

Institute for Computational Design and Construction, University of Stuttgart

Prof. Achim Menges, Tiffany Cheng, Ekin Sila Sahin, Dylan Wood, Yasaman Tahouni

Scientific Assistants: Ahmad Razavi, Seyed Mobin Moussavi, Nicolas Kubail Kalousdian, Robert Faulkner, Jorge Christie, Maria Razzhivina, Farnaz Fattahi

INDUSTRIAL PROJECT PARTNERS

A THIEME GmbH & Co. KG Drucksysteme (Teningen)

3D-LABS (St. Georgen)

BASF SE (Ludwigshafen)

ePainter (Freiburg)

Ortema GmbH (Markgröningen)

Uvex Sports Group GmbH & Co KG (Fürth)

Stryker Leibinger GmbH & CO. KG (Freiburg)

PROJECT FUNDING

Baden-Württemberg Stiftung - Ausschreibung Innovation durch Additive Fertigung (4DmultiMATS)

RELATED PUBLICATIONS

Sahin, E.S., Cheng, T., Wood, D., Tahouni, Y., Poppinga, S., Thielen, M., Speck, T., Menges, A.: 2023, Cross-Sectional 4D-Printing: Upscaling Self-Shaping Structures with Differentiated Material Properties Inspired by the Large-Flowered Butterwort (Pinguicula grandiflora). Biomimetics, vol. 8, no. 2. (DOI: 10.3390/biomimetics8020233)

Cheng, T., Thielen, M., Poppinga, S., Tahouni, Y., Wood, D., Steinberg, T., Menges, A., Speck, T.: 2023, Entwicklung bioinspirierter und selbstformender Orthesen per 4D-Druck. Orthopädie Technik, vol. 74, no. 1. (Available Online)

Cheng, T., Thielen, M., Poppinga, S., Tahouni, Y., Wood, D., Steinberg, T., Menges, A., Speck, T.: 2021, Bio‐Inspired Motion Mechanisms: Computational Design and Material Programming of Self‐Adjusting 4D‐Printed Wearable Systems. Advanced Science, 2100411. (DOI: 10.1002/advs.202100411)

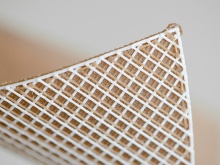

Cheng, T., Tahouni, Y., Wood, D., Stolz, B., Mulhaupt, R., Menges, A.: 2020, Multifunctional Mesostructures: Design and Material Programming for 4D-printing. In Symposium on Computational Fabrication (SCF '20). ACM, New York, NY, USA. (DOI: 10.1145/3424630.3425418)

CONFERENCE PRESENTATIONS & INVITED TALKS

- 2023 Cross-Sectional 4D-Printing (CS4DP) London Design Biennale 2023, Somerset House, UK

- 2021 4D-printed motion mechanisms inspired by Dioscorea bulbifera Mécanique et Physique des Systèmes Complexes, ESPCI Paris, FR

- 2020 Multifunctional Mesostructures: Design and Material Programming for 4D-printing Symposium on Computational Fabrication, Boston, USA

- 2020 4D-printing of Self-adjusting and Multifunctional Material Systems Forschungstag, Stuttgart, DE

- 2020 Self-Shaping Smart Structure: Computational Design and 4D-Printing for Surface Shifting Material Systems Inspired by the Butterwort Living Materials, Saarbrücken, DE

- 2019 Smart Structure: Computational Design for 4D-Printed Material Systems Inspired by the Butterwort EUROMAT, Stockholm, SE

SELECTED PRESS

PROJECT INFORMATION

Tiffany Cheng, University of Stuttgart, Institute for Computational Design and Construction

Contact information

Yerong Huang

Dr., B.Des Arch., B.Eng. Hons (Civil)Senior Research Associate | Material Programming